Substation | What is Substation | Electric Substation | GIS Substation | Gas Insulated Substation | Types of Substation | Substation Equipment | Electric Substation Design

As our modern society heavily relies on electricity for various aspects of daily life, electrical substations play a crucial role in the efficient and reliable distribution of electrical power. In this article, we will delve into the world of electrical substations, exploring their types, components, and importance in the power grid. An electrical substation is a key element in the power grid that serves as a hub for transforming and distributing electricity. It acts as an intermediary point between the power generation station and the end consumers, ensuring that electricity is safely and efficiently delivered to homes, businesses, and industries.

Types of Electrical Substations

Electrical substations can be categorized into different types based on their functions and locations. Some common types of electrical substations include:

Step-up Substation:

These substations are typically located near power generation stations and are responsible for increasing the voltage of electricity before it is transmitted through long-distance power lines to reduce power losses.

Step-down Substation:

These substations are located closer to the end consumers and are responsible for reducing the voltage of electricity before it is distributed to homes, businesses, and industries.

Distribution Substation:

These substations are responsible for distributing electricity to various areas within a local community or region.

Transmission Substation:

These substations are located along high-voltage transmission lines and are responsible for transforming and transferring electricity from power generation stations to distribution substations.

Air Insulated Substations (AIS)

Air Insulated Substations (AIS) are the traditional type of substations that use air as the medium for insulation and cooling. They are commonly used in electrical power distribution systems and consist of various components, such as switchgear, transformers, and busbars, that are arranged in an open-air configuration.

Gas Insulated Substations (GIS)

Gas Insulated Substations (GIS) are high-voltage substations that use a gas-insulated switchgear (GIS) for their primary and secondary electrical equipment. The GIS equipment consists of various components, including circuit breakers, disconnect switches, grounding switches, voltage transformers, current transformers, and surge arresters. The GIS equipment is designed to operate at high voltages and can handle large power capacities.

The following are some of the specifications and ratings of GIS substations:

Voltage Level:

GIS substations are typically designed to operate at high voltage levels, ranging from 72.5 kV to 800 kV. The voltage level depends on the application and the power capacity of the substation.

Power Capacity:

The power capacity of a GIS substation can vary from a few hundred megawatts (MW) to several thousand MW. The capacity depends on the voltage level, the size of the substation, and the load requirements.

Compactness:

GIS substations are designed to be compact, which makes them suitable for applications where space is limited. The GIS equipment takes up much less space compared to air-insulated substations (AIS) of the same capacity.

Safety:

GIS substations are designed to be safe and reliable. The use of SF6 gas as an insulation medium reduces the risk of fire or explosion in the substation. The GIS equipment is also designed to withstand seismic events and other natural disasters.

Reliability:

GIS substations are highly reliable and require very little maintenance compared to AIS substations. The sealed design of the GIS equipment protects it from dust, moisture, and other contaminants, resulting in a longer service life and lower maintenance costs.

Environmental Friendliness:

The use of SF6 gas as an insulating medium has a very low impact on the environment as the gas is non-toxic, non-flammable, and has a very low global warming potential. The GIS equipment is also designed to be recyclable, reducing its impact on the environment

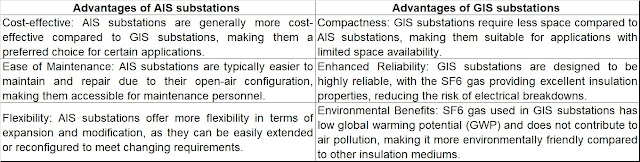

Types of AIS and GIS Substations

Both AIS and GIS substations can be further categorized into different types based on their configurations and applications. Some common types of AIS and GIS substations include:

Indoor AIS Substations:

These substations are housed in a building and provide protection against environmental elements. They are commonly used in urban areas where space is limited.

Outdoor AIS Substations:

These substations are installed in an open-air configuration and are commonly used in rural areas where space is abundant.

Conventional GIS Substations:

These substations use standard GIS technology and are typically used in medium to high voltage applications, such as in urban areas or for industrial complexes.

Hybrid GIS Substations:

These substations combine GIS technology with AIS components, providing a more cost-effective solution for certain applications.

Architecture of GIS system

The architecture of a Gas Insulated Substation (GIS) system includes various components that work together to provide reliable and efficient power transmission and distribution. Here's a breakdown of the GIS system architecture:

GIS Equipment:

The core component of the GIS system is the gas-insulated switchgear (GIS) equipment. It is made up of various components, with active parts situated in the center of aluminium alloy pipes and held in place by epoxy resin insulators. The pipes are filled with insulating gas and are grounded.This equipment consists of various components such as circuit breakers, disconnect switches, grounding switches, voltage transformers, current transformers, and surge arresters. The GIS equipment is designed to operate at high voltages and can handle large power capacities.

Busbars:

The busbars are an essential component of the GIS system, as they provide the means of transporting power from the power source to the load. The busbars are made of high conductivity materials such as copper or aluminum.

Control and Protection System:

The control and protection system is responsible for monitoring and controlling the GIS equipment to ensure safe and reliable operation. The system includes various sensors, relays, and control devices that monitor the status of the GIS equipment and provide feedback to the control system.

Communication System:

The communication system is used to transmit data between the control and protection system and the GIS equipment. The system includes various communication protocols such as IEC 61850, DNP3, and Modbus.

Auxiliary Equipment:

The auxiliary equipment includes various components such as transformers, battery banks, and HVAC systems that provide support functions for the GIS system. The auxiliary equipment ensures that the GIS equipment is operating at optimal conditions and provides backup power in case of a power failure.

Enclosure:

The GIS equipment is housed in an enclosure that is designed to protect the equipment from environmental factors such as dust, moisture, and temperature fluctuations. The enclosure is typically made of steel or aluminium and is designed to be durable and long-lasting.

Components of Electrical Substations

Electrical substations consist of several components that work together to ensure the safe and efficient distribution of electricity. Some common components of electrical substations include:

Transformers:

Transformers are essential components of electrical substations that are responsible for changing the voltage of electricity. Step-up transformers increase the voltage, while step-down transformers decrease the voltage to suitable levels for distribution.

Circuit Breakers:

Circuit breakers are protective devices that help prevent overloads and short circuits in the electrical system by interrupting the flow of electricity when necessary.

Switchgear:

Switchgear refers to the collection of switches, fuses, and other control devices that are used to control, protect, and isolate electrical equipment in substations.

Busbars:

Busbars are conductive bars that are used to distribute electrical power to different areas within the substation.

Importance of Electrical Substations

Electrical substations are crucial for the reliable and efficient distribution of electricity. Some key reasons why electrical substations are important include:

Power Distribution: Electrical substations ensure that electricity is distributed to homes, businesses, and industries in a safe and efficient manner, meeting the energy demands of modern society.

Voltage Regulation: Electrical substations play a vital role in regulating the voltage of electricity to suitable levels for transmission and distribution, ensuring that electrical appliances and equipment receive the correct voltage to operate efficiently and safely.

Power Quality: Electrical substations monitor and maintain the quality of electricity, including factors such as voltage levels, frequency, and power factor, to ensure that electricity is delivered without interruptions or fluctuations.

Safety and Reliability: Electrical substations are designed with various safety features and redundancy measures to ensure the reliable and uninterrupted supply of electricity, preventing power outages and minimizing downtime.

Applications of AIS and GIS Substations

Power Generation:

AIS and GIS substations are used in power generation plants to step up the generated power to a higher voltage level for transmission over long distances. The substations help to ensure the reliability and quality of the power delivered to the distribution grid.

Power Transmission:

AIS and GIS substations are used in power transmission systems to step up the voltage level of the power for efficient long-distance transmission over high voltage power lines. The substations help to reduce power losses and ensure the reliable and stable operation of the transmission system.

Distribution:

AIS and GIS substations are used in power distribution systems to step down the voltage level of the power for safe and efficient distribution to residential, commercial, and industrial customers. The substations help to regulate the voltage, reduce power losses, and improve the reliability of the distribution system.

Renewable Energy:

AIS and GIS substations are increasingly being used in renewable energy systems, such as wind and solar power, to connect the power generated by renewable sources to the grid. The substations help to ensure the stability and quality of the power delivered to the grid and to manage the intermittency and variability of the renewable energy sources.

Industrial Applications:

AIS and GIS substations are used in various industrial applications, such as mining, oil and gas, and manufacturing, to provide reliable and stable power supply to industrial facilities. The substations help to regulate the voltage, reduce power losses, and improve the power quality for industrial processes.

Railway Electrification:

AIS and GIS substations are used in railway electrification systems to step down the voltage level of the power for safe and efficient distribution to railway traction substations. The substations help to provide reliable and stable power supply to trains and ensure the safety and efficiency of railway operations.

Data Centers:

AIS and GIS substations are used in data center applications to provide reliable and stable power supply to critical IT infrastructure. The substations help to regulate the voltage, reduce power losses, and improve the power quality for uninterrupted data center operations.

Substation Automation System

Substation Automation System (SAS) is a modern solution that leverages advanced communication and automation technologies to remotely monitor, control, and automate electrical substations. SAS enables utilities and grid operators to efficiently manage and optimize the operation of substations, leading to improved reliability, enhanced safety, and reduced maintenance costs.

Benefits of Substation Automation System

SAS offers numerous benefits to utilities and grid operators. Some of the key benefits include:

Enhanced Reliability:

SAS enables real-time monitoring of various parameters such as voltage, current, temperature, and fault detection, allowing for timely detection and resolution of issues, thus improving the reliability of the power distribution system.

Increased Efficiency:

SAS automates various tasks such as data collection, fault analysis, and switchgear control, reducing the need for manual intervention and optimizing the operation of substations, leading to increased efficiency.

Improved Safety:

SAS allows for remote operation of substations, reducing the need for field personnel to physically access substations, thereby minimizing the risk of accidents and ensuring the safety of workers.

Reduced Downtime:

SAS enables quick detection and isolation of faults, leading to faster restoration of power and reduced downtime during outages.

Cost Savings:

SAS optimizes the operation of substations, reducing maintenance costs, minimizing equipment failures, and prolonging the lifespan of substation components, resulting in cost savings for utilities.

Components of Substation Automation System

SAS comprises several components that work together to enable remote monitoring, control, and automation of substations. Some of the key components include:

Remote Terminal Units (RTUs):

RTUs are installed at the substations and collect data from various sensors and devices, such as circuit breakers, transformers, and relays. RTUs communicate the collected data to the central control center for analysis and control.

Communication Network:

A robust communication network is essential for transmitting data between the substations and the central control center. This can be achieved through various communication technologies such as Ethernet, fiber optic, and wireless communication.

SCADA System:

The Supervisory Control and Data Acquisition (SCADA) system is the central control center that manages and monitors the data collected from the substations. SCADA systems provide operators with real-time information about the status of the substations and allow them to remotely control and automate various operations.

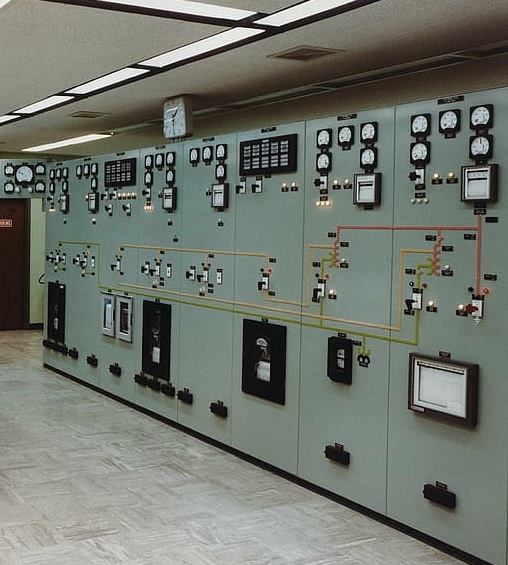

Human-Machine Interface (HMI):

HMIs are graphical interfaces that provide operators with a user-friendly way to interact with the SCADA system. HMIs allow operators to monitor the status of the substations, visualize data, and control devices remotely.

Applications of Substation Automation System

SAS finds applications in various settings, including:

Power Utilities:

SAS is widely used by power utilities for efficient management of substations, enabling remote monitoring, control, and automation of substations across the power grid.

Renewable Energy Systems:

SAS is used in renewable energy systems, such as solar and wind farms, to monitor and control the power generation and distribution process.

Industrial Complexes:

SAS is employed in industrial complexes to monitor and control the electrical substations that power the industrial processes, improving reliability and efficiency.

Smart Grids:

SAS plays a crucial role in the implementation of smart grid technologies, enabling advanced monitoring, control, and automation of substations for efficient and sustainable power distribution.

Setting and monitoring protective relays of substation

Protective relays are critical devices that are installed in electrical substations to detect and respond to abnormal electrical conditions, such as overloads, short circuits, and faults. They play a crucial role in protecting substation equipment, preventing damage, and ensuring safe and reliable power distribution to consumers.

Importance of Relay Setting in Substations

Relay setting is a critical process that involves configuring the protective relays to operate within specified parameters based on the electrical characteristics of the substation equipment and the power system network. Proper relay setting is essential to ensure reliable and coordinated protection of substation equipment. Some key aspects of relay setting include:

Coordination:

Relays in a substation need to be coordinated with each other to ensure that they operate in a coordinated and sequential manner. This prevents false tripping of relays and minimizes the impact of faults on the power system.

Sensitivity:

Relay settings need to be sensitive enough to detect faults and abnormal conditions accurately. However, they should also be set to avoid unnecessary tripping and disruption of power supply during normal operating conditions.

Time Delay:

Relay settings include time delays that determine the response time of the relays. Proper time delay settings ensure that the relays respond quickly to faults while allowing for fault clearing and coordination with other protective devices.

Selectivity:

Relay settings should be selective, meaning that only the relay closest to the fault should operate to isolate the faulted section, while the rest of the system remains operational. This ensures minimal disruption to the power supply and efficient fault clearance.

Importance of Relay Monitoring in Substations

Relay monitoring is essential to ensure that protective relays are functioning correctly and reliably. Regular monitoring allows for early detection of any issues or abnormalities in the relay operation and enables timely corrective actions. Some key aspects of relay monitoring include:

Testing:

Regular testing of protective relays using appropriate testing equipment and procedures helps to verify their correct operation and detect any issues or malfunctions. Testing should be performed during scheduled maintenance activities and whenever any changes or modifications are made to the substation equipment.

Data Analysis:

Monitoring and analyzing the data from the relays, including fault records, event logs, and performance data, helps to identify patterns, trends, and anomalies in relay operation. This enables proactive maintenance and troubleshooting to prevent potential failures and ensure reliable operation.

Alarm Management:

Relay monitoring systems often include alarm features that alert operators of any abnormal conditions or relay malfunctions. Proper alarm management, including setting up alarm thresholds, notifications, and response protocols, helps to ensure timely and effective action in case of relay issues.

Maintenance of Protective Relays in Substations

Regular maintenance of protective relays is crucial to ensure their reliable operation. Some key aspects of relay maintenance include:

Cleaning and Inspection:

Protective relays should be regularly cleaned and inspected for dust, dirt, corrosion, and physical damage. Any issues should be addressed promptly to prevent interference with relay operation.

Firmware/Software Updates:

Relay manufacturers often release firmware or software updates that provide bug fixes, performance improvements, and new features. Regular updates should be applied to keep the relays up-to-date and ensure optimal performance.

Calibration:

Relays should be calibrated periodically to ensure their accuracy and reliability. Calibration involves verifying the relay settings and parameters against known standards and making necessary adjustments as required.

Control and monitoring auxiliary power system of substation

Auxiliary power systems in substations provide the necessary electrical power to support the operation of substation equipment and systems, such as control panels, communication systems, protection relays, and lighting. These systems are critical for maintaining reliable and efficient operation of the substation, even during power outages or disruptions in the main power supply.

Importance of Control of Auxiliary Power Systems

Control of auxiliary power systems involves managing and regulating the operation of various components, such as backup power sources, battery banks, and DC systems, to ensure their availability and reliability. Some key aspects of control of auxiliary power systems include:

Backup Power:

Backup power sources, such as diesel generators or uninterruptible power supply (UPS) systems, are often used to provide emergency power during power outages. Proper control of backup power sources ensures their timely activation, smooth transition, and optimal operation to avoid any disruption to the substation operation.

Battery Banks:

Battery banks are used to provide DC power for various substation equipment, including protection relays and control panels. Control of battery banks involves monitoring their state of charge, voltage levels, and temperature, as well as ensuring proper charging and discharging cycles to extend their lifespan and ensure their availability during emergencies.

DC Systems:

DC systems, such as rectifiers, inverters, and converters, are used to convert AC power to DC power for various substation applications. Control of DC systems includes monitoring their performance, efficiency, and reliability, as well as managing their operation and maintenance to ensure their optimal performance and minimize downtime.

Importance of Monitoring of Auxiliary Power Systems

Monitoring of auxiliary power systems involves continuous surveillance and analysis of various parameters and performance data to detect any abnormalities or potential issues early on and take timely corrective actions. Some key aspects of monitoring of auxiliary power systems include:

Real-time Monitoring:

Real-time monitoring of auxiliary power systems allows for continuous surveillance of critical parameters, such as voltage, current, temperature, and state of charge, to detect any deviations from normal operation. This enables prompt identification and resolution of issues, minimizing downtime and ensuring reliable operation.

Data Analysis:

Monitoring and analyzing the data from auxiliary power systems, including performance logs, alarms, and event records, helps to identify patterns, trends, and anomalies in their operation. This allows for proactive maintenance and troubleshooting, preventing potential failures and optimizing performance.

Alarm Management:

Monitoring systems often include alarm features that alert operators of any abnormal conditions or potential issues in auxiliary power systems. Proper alarm management, including setting up alarm thresholds, notifications, and response protocols, ensures timely and effective action in case of any deviations from normal operation.

Maintenance of Auxiliary Power Systems

Regular maintenance of auxiliary power systems is crucial to ensure their reliable operation. Some key aspects of maintenance of auxiliary power systems include:

Inspection and Testing:

Auxiliary power systems should be regularly inspected and tested for proper operation, including checking the condition of backup power sources, battery banks, and DC systems. Any issues should be addressed promptly to prevent any disruption to the substation operation.

Cleaning and Corrosion Prevention:

Auxiliary power systems should be kept clean and free from dust, dirt, and corrosion, which can affect their performance and reliability. Regular cleaning and application of corrosion prevention measures are essential to ensure optimal operation and longevity.

Battery Maintenance:

Battery banks require specific maintenance, such as periodic checking of their state of charge, voltage levels, and temperature, as well as equalization charging and replacement of degraded batteries. Proper battery maintenance practices, as per the manufacturer's recommendations, should be followed to extend their lifespan and ensure their availability during emergencies.

Calibration and Testing of Protective Relays:

Protective relays are an important part of auxiliary power systems, as they monitor and control various aspects of substation equipment. Regular calibration and testing of protective relays should be conducted to ensure their accuracy and reliability in detecting and responding to abnormal conditions.

Benefits of Effective Control and Monitoring of Auxiliary Power Systems

Efficient control and monitoring of auxiliary power systems in substations offer several benefits, including:

Enhanced Reliability:

Proper control and monitoring of auxiliary power systems ensure their availability during emergencies, such as power outages, equipment failures, or natural disasters, minimizing downtime and ensuring reliable operation of the substation.

Improved Efficiency:

Real-time monitoring and analysis of performance data help in identifying inefficiencies, suboptimal operation, or potential issues in auxiliary power systems. Timely corrective actions can be taken to optimize their performance, reduce energy waste, and improve overall efficiency of the substation.

Proactive Maintenance:

Effective monitoring of auxiliary power systems allows for proactive maintenance, including timely repairs, replacements, and upgrades, based on their actual condition and performance data. This helps in preventing unexpected failures, reducing downtime, and extending the lifespan of the equipment.

Enhanced Safety:

Auxiliary power systems, such as backup power sources and battery banks, can pose safety risks if not properly controlled and monitored. Effective control and monitoring help in detecting and mitigating potential safety hazards, ensuring a safe working environment for substation personnel.

Cost Savings:

Optimized operation, proactive maintenance, and improved efficiency of auxiliary power systems result in cost savings in terms of reduced downtime, lower energy waste, and extended equipment lifespan. This leads to overall cost-effective operation of the substation.

Precautions and Safety guidelines for substation

Substations are critical facilities that require strict adherence to safety guidelines and precautions to ensure the safety of personnel, equipment, and the surrounding environment. Here are some important precautions and safety guidelines for substation operations:

Electrical Safety:

Substations involve high voltages and currents, which can pose a serious risk of electrical hazards. It is essential to follow proper electrical safety procedures, such as wearing appropriate personal protective equipment (PPE) like gloves, goggles, and insulated clothing, when working in or around substations. Only qualified personnel should be allowed to work on live electrical equipment, and proper lockout/tagout procedures should be followed during maintenance and repair activities.

Fire Safety:

Substations may have various sources of ignition, such as electrical faults, equipment failures, or external factors like lightning strikes. Proper fire prevention and protection measures, such as fire-resistant construction, fire detection and suppression systems, and regular inspection of electrical equipment for signs of overheating or arcing, should be in place. Adequate firefighting equipment, training, and emergency response plans should also be established.

Access Control:

Unauthorized access to substations can be dangerous and pose security risks. Strict access control measures, such as physical barriers, locks, alarms, and surveillance systems, should be implemented to prevent unauthorized entry. Only authorized personnel with proper training and qualifications should be allowed to enter substations.

Proper Equipment Handling:

Substation equipment, such as transformers, switchgear, and circuit breakers, are heavy and require proper handling techniques. Adequate lifting equipment and procedures should be followed to prevent injuries or equipment damage during installation, maintenance, or repair activities. Proper equipment grounding and bonding practices should also be followed to avoid electric shock hazards.

Hazardous Materials Handling:

Substations may contain hazardous materials, such as insulating oils, SF6 gas, and lead-acid batteries. Proper handling, storage, and disposal of hazardous materials should be in accordance with applicable regulations and industry best practices. Personnel should be trained in handling hazardous materials and follow proper procedures to minimize the risk of exposure and environmental pollution.

Emergency Preparedness:

Substations should have well-defined emergency response plans in place, including evacuation procedures, first aid kits, emergency shutdown procedures, and communication protocols. Personnel should be trained in emergency response procedures and periodically drill to ensure their readiness to handle emergencies, such as electrical faults, fires, or chemical spills.

Maintenance and Testing:

Regular maintenance and testing of substation equipment are essential to ensure their safe and reliable operation. Maintenance and testing should be performed by qualified personnel following proper procedures and manufacturer's recommendations. Proper lockout/tagout procedures should be followed during maintenance activities to prevent accidental energization of equipment.

Training and Education:

Personnel working in substations should receive proper training and education on substation safety procedures, including electrical safety, fire safety, equipment handling, hazardous materials handling, emergency response, and maintenance and testing procedures. Regular refresher training should be provided to ensure personnel are updated on the latest safety guidelines and practices.

Compliance with Regulations:

Substations are subject to various local, national, and international regulations, codes, and standards. It is important to comply with all applicable regulations, such as OSHA, NFPA, NEC, and IEEE, to ensure safe and compliant operation of substations.

Conclusion:

In conclusion, electrical substations are critical facilities that play a crucial role in the reliable and efficient distribution of electricity. Understanding their types, components, and importance in the power grid is

Safety should be the top priority in substation operations. Strict adherence to safety guidelines and precautions, proper training and education of personnel, and compliance with regulations are crucial for preventing accidents, protecting personnel, and ensuring the reliable operation of substations. Regular safety audits, inspections, and reviews should be conducted to identify and address potential safety hazards in substations.

FAQ

Q: What is the function of substation?

A: The function of a substation is to convert high voltage electrical power from the transmission system to lower voltage suitable for distribution to homes and businesses. Substations also provide switching and protective functions to ensure reliable and safe power supply.

Q: What are the three types of substations?

A: The three types of substations are transmission substations, distribution substations, and collector substations. Transmission substations step down the voltage from the transmission line to the distribution level, while distribution substations further reduce the voltage for local distribution. Collector substations are used in renewable energy generation systems to collect and step up power from wind or solar farms.

Q: What is the difference between substation and transformer?

A: A transformer is an electrical device that transfers electrical energy from one circuit to another by means of electromagnetic induction, while a substation is a facility that transforms voltage levels, switches circuits, and regulates the flow of electrical power. Transformers are often found in substations as a key component, but a substation is a complete system with additional components such as switchgear, protective relays, and control systems.

Q: Why is substation called substation?

A: The term "substation" comes from the fact that it is a secondary station in the electrical power transmission and distribution system, located downstream from the primary or generating station. Substations are used to transform the high voltage power transmitted over long distances to lower voltages suitable for distribution.

Q: What is GIS in a substation?

A: GIS stands for Gas Insulated Substation, which is a type of substation where the electrical equipment is enclosed in a sealed environment filled with sulfur hexafluoride (SF6) gas. GIS systems are more compact and require less space than conventional Air Insulated Substations (AIS).

Q: What is the difference between AIS and GIS substation?

A: The main difference between AIS (Air Insulated Substation) and GIS (Gas Insulated Substation) is the type of insulation used to enclose the electrical equipment. AIS substations use air as the insulation medium, while GIS substations use SF6 gas. GIS systems have a smaller footprint and require less maintenance, but are typically more expensive than AIS systems.

Q: What is GIS in electrical system?

A: GIS stands for Gas Insulated Switchgear, which is a type of electrical equipment used in power transmission and distribution systems. GIS systems use SF6 gas as the insulation medium and are more compact and require less space than conventional Air Insulated Switchgear (AIS) systems.

Q: Why SF6 is used in GIS?

A: SF6 gas is used in GIS systems due to its excellent insulating and arc-quenching properties. It has a high dielectric strength and is chemically stable, making it an ideal insulation medium. Additionally, SF6 gas has a high heat transfer capability, allowing for efficient cooling of the electrical equipment.

Post a Comment