Motor | Motor Specification

Motors play a vital role in various aspects of our daily lives, powering devices and machines that we rely on for transportation, manufacturing, and everyday convenience. They are essential for converting electrical or chemical energy into mechanical energy, enabling the movement and operation of numerous systems. In this article, we will explore different types of motors, their working principles, applications, advantages, and future trends in motor technology.

Introduction

Motors are devices that convert one form of energy into mechanical energy to perform work. They are found in a wide range of applications, from powering industrial machinery to propelling vehicles. Without motors, many of the technologies and conveniences we take for granted would not exist.

Types of Motors

Electric motors are the most common type of motor used today. They rely on the principles of electromagnetic induction to generate rotational motion. There are two main categories of electric motors: DC motors and AC motors.

DC Motors

DC motors operate on direct current (DC) and are widely used in applications such as electric vehicles, robotics, and small appliances. They consist of a stator (stationary part) and a rotor (rotating part) connected to an axle. When an electric current is passed through the stator, it creates a magnetic field that interacts with the permanent magnets on the rotor, causing it to rotate.

AC Motors

AC motors, on the other hand, operate on alternating current (AC). They are commonly used in industrial machinery, household appliances, and HVAC systems. AC motors can be further classified into synchronous and induction motors. Synchronous motors maintain a constant speed that is synchronized with the frequency of the power source, while induction motors operate at slightly lower speeds.

Working Principles of Motors

Electric motors operate based on the principles of electromagnetic induction. When an electric current flows through a wire coil in the presence of a magnetic field, it experiences a force that causes the coil to rotate. This rotational motion is harnessed to perform work. Electric motors consist of several components, including:

Electromagnetic Induction

The core principle behind electric motor operation is electromagnetic induction. By passing an electric current through a wire coil, a magnetic field is created around the coil. This magnetic field interacts with the magnetic field of the rotor, resulting in rotational motion.

Motor Components

Electric motors consist of several essential components, including the stator, rotor, commutator (in DC motors), and brushes (in some types of DC motors). The stator contains the wire coils and generates the magnetic field, while the rotor is the rotating part that interacts with the stator's magnetic field. The commutator, found in DC motors, ensures that the direction of the electric current in the rotor changes at the appropriate time, allowing for continuous rotation.

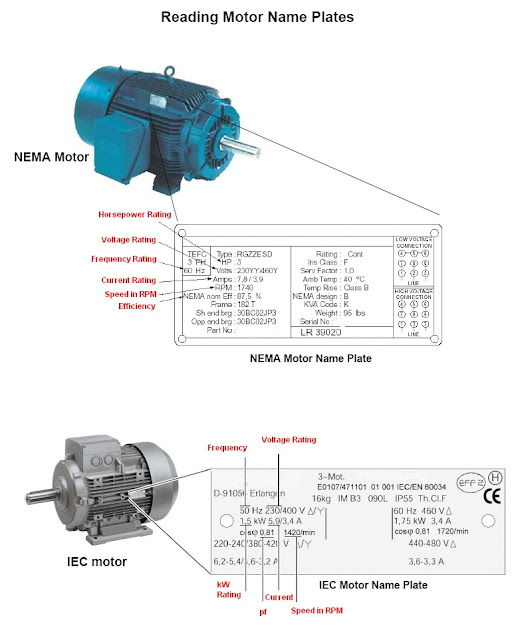

Reading Motor Nameplate Information

NEMA MG-1 requires that certain information be included on the nameplate of all single- and three-phase motors. Typical nameplate information includes horsepower, volts, amps, Hz, phase, rpm, insulation class, enclosure, frame size, efficiency, service factor, power factor, duty, ambient, code and design. Most are straightforward but, there are several that require further explanation.

AC Motors Frame Size

The frame sizes i.e. physical dimensions of AC motors have changed substantially through the years. Earlier, Motors were considerably larger than those in use today. This increased size was the result of inefficiency and the need to dissipate heat.

A particular motor might be built on several different frames. There was not much standardization, and it has made replacement more difficult since the dimensions, including shaft height and the placement of the base mounting holes, could also change.

As new materials and advanced design techniques became available, the frame size necessary to produce a particular horsepower was reduced and, eventually, size standardization became the norms.

Frame Size Coding

The three digits that make up the frame size are directly related to the dimensions of the motor built on that particular frame. The first two digits of the frame size when divided by four will result in the height of the shaft center line above the bottom of the mounting foot. For a 225 frame shaft height would be 5.5 inches (22/4 = 5.5). See above chart

Although there is no inch reference, the third digit is indicative of the distance from the motor's vertical center line to the front and rear foot-mounting holes. It is also indicative of the overall motor length.

In addition to the standard, three digit nomenclature, an alphabetical suffix is added to designate any modifications to the standard T frame design Motor Frame Size chart

Efficiency

Efficiency (Eff) defines how well a motor converts electrical energy into mechanical energy. The motor's full load efficiency is shown on the nameplate, and it is often less than the actual maximum efficiency. Maximum motor efficiency typically occurs between 70 percent and 95 percent of full load, and most NEMA motors can be operated as low as 60 percent of full load without any significant loss in efficiency. This allows the flexibility of upgrading to the next higher horsepower when loading is at or very near the full load capacity of the lower horsepower motor.

Service Factor

Service factor (SF) is an often misunderstood piece of information. SF is a multiplier that indicates the actual horsepower that the motor can deliver over and above the nameplate horsepower. For example, if a 10 horsepower motor has an SF of 1.15, it is designed to deliver 11.5 horsepower without overloading.

SF is intended to handle small, intermittent overloads, occasional increases in ambient temperature and periods when the actual voltage is lower than the nameplate voltage. For example, a typical 10 horsepower, 230-volt motor draws approximately 24 amps at full load. If the voltage is reduced to 200 volts, the current increases to 28 amps, which is the normal current draw of an 11.5 horsepower motor.

Therefore, a 230-volt motor with a 1.15 SF can accommodate such a short-term voltage drop. However, it should not be operated on a true 200/208-volt circuit since there would be no remaining SF available to accommodate any additional drop in voltage.

Power Factor

Power factor (PF) is the ratio of active power in watts to the apparent power in volts/amps at full load. A motor can be designed for high efficiency or high PF but not both. Since efficiency cannot be enhanced in the field, motors are designed for high efficiency and the trade off is lower PF. Fortunately, PF can be easily increased in the field by adding an appropriate capacitor to the circuit.

Duty

Duty defines the length of time that the motor can operate while meeting its other nameplate ratings. Most industrial motors are rated continuous (or cont.) while certain special application motors will show intermittent run times in minutes. In the absence of any indication of the rated duty type, continuous running duty is assumed when considering motor operation.

The duty types are indicated by the symbols S1...S10 according to IEC 600 34-1 and VDE 0530 Part 1.

S1

|

Continuous

duty

|

The motor works at a constant load for enough time to reach

temperature equilibrium.

|

S2

|

Short-time

duty

|

The motor works at a constant load, but not long enough to reach

temperature equilibrium. The rest periods are long enough for the motor to

reach ambient temperature.

|

S3

|

Intermittent

periodic duty

|

Sequential, identical run and rest cycles with constant load.

Temperature equilibrium is never reached. Starting current has little effect

on temperature rise.

|

S4

|

Intermittent

periodic duty with starting

|

Sequential, identical start, run and rest cycles with constant

load. Temperature equilibrium is not reached, but starting current affects

temperature rise.

|

S5

|

Intermittent

periodic duty with electric braking

|

Sequential, identical cycles of starting, running at constant

load and running with no load. No rest periods.

|

S6

|

Continuous

operation with intermittent load

|

Sequential, identical cycles of running with constant load and

running with no load. No rest periods.

|

S7

|

Continuous

operation with electric braking

|

Sequential identical cycles of starting, running at constant

load and electric braking. No rest periods.

|

S8

|

Continuous

operation with periodic changes in load and speed

|

Sequential, identical duty cycles run at constant load and given

speed, then run at other constant loads and speeds. No rest periods.

|

Ambient Temperature

Ambient temperature is the maximum allowable temperature of the air surrounding a motor when it is operated continuously at full load.

A typical ambient rating is 40 Deg C F-Class (155 Deg C). The actual operating temperature is the sum of the ambient temperature and the internal temperature rise at full load.

Temperature

Tolerance Class

|

Maximum Operation Temperature

Allowed

|

Allowable Temperature Rise at

full load; 1.0 service factor motor

|

Allowable Temperature Rise at full load; 1.15 service factor

motor

|

|

oC

|

oF

|

oC

|

oC

|

|

A

|

105

|

221

|

60

|

70

|

B

|

130

|

266

|

80

|

90

|

F

|

155

|

311

|

105

|

115

|

H

|

180

|

356

|

125

|

-

|

For example, Class B insulation is rated at 130 degrees H and is designed to handle an internal temperature rise of 155 Deg C (assumes a 1.15 SF) when operating in a 40 Deg C ambient environment.

Motor Enclosures

Motors have two basic types of enclosures—open and enclosed. Open enclosures allow for the free flow of air through the motor internals while those that are enclosed greatly restrict or prohibit the entry of outside air. The basic designs used in applications are described below.

1) Open Drip Proof

The open drip proof (ODP) enclosure is intended for installation in clean and dry environments and tends to be the standard in the HVAC industry and other clean, indoor applications. An internal fan circulates ambient air through the enclosure and provides a highly efficient cooling process.

2)Totally Enclosed Fan Cooled

The totally enclosed fan cooled (TEFC) enclosure is designed for outdoor installation and dirty or dusty indoor applications. Special TEFC designs are also used in processing plants in which periodic wash down is required. Unlike the ODP enclosure, it uses an external fan to force ambient air over the motor's exterior surface. Cooling is not as efficient as that of the ODP enclosure and service factor (SF) is sometimes limited to unity (1.0). The totally enclosed fan cooled (TEFC) motor is the predominant standard

for industrial applications today. The versatile TEFC is fully enclosed within the motor frame, with cooling air directed over it by an externally mounted fan.

3)Totally Enclosed Air Over

The totally Enclosed Air Over (TEAO) enclosure is designed for damp or wet environments in which the driven machine provides the air flow required for cooling. A common application is cooling tower fans. TEAO motors often have multiple horsepower ratings, and the usable horsepower depends upon the velocity and temperature of the air flowing over the motor.

4)Totally Enclosed Non-Ventilated

The totally enclosed non-ventilated (TENV) enclosure is designed for dusty environments and is usually limited to 5 horsepower and less. It uses the motor surface area to transfer heat to the surrounding air without the aid of an external fan.

5) Hazardous Locations

Hazardous location motors are a totally enclosed design that are intended for use in potentially dangerous areas. The Class I, Explosion Proof (XP) enclosure is a special type that is designed for use in locations in which potentially explosive liquids and gases may be present. Class II enclosures are used in locations that are subject to combustible dusts, such as coal and grains. The area where the rotor shaft exits the enclosure is designed to contain any sparks that could occur inside the motor enclosure.

Speed

The induction motor is a fixed single speed machine. Its speed is dependent on the frequency of the electricity supply and the stator winding design.

No load speed is slightly lower than synchronous speed due to the no load losses in the machine.

Frequency X 120

Synchronous Speed= -----------------------

Motor Poles

Full load speed is typically a further 3-4 per cent lower than no load speed.

Motor

Speed

|

||||

50 Hz

Speed in RPM

|

60 Hz

Speed in RPM

|

|||

Poles

|

Synchronous

|

Typical

full load

|

Synchronous

|

Typical

full load

|

2

|

3

|

2.9

|

3.6

|

3.45

|

4

|

1.5

|

1.44

|

1.8

|

1.74

|

6

|

1

|

960

|

1.2

|

1.15

|

8

|

750

|

720

|

900

|

850

|

10

|

600

|

580

|

720

|

700

|

12

|

500

|

480

|

600

|

580

|

16

|

375

|

360

|

450

|

430

|

Applications of Motors

Motors have a wide range of applications across various industries and everyday life. Here are some notable examples:

A. Industrial Applications

1. Manufacturing

Motors are extensively used in manufacturing processes, powering conveyor belts, robotic arms, assembly lines, and other machinery. They enable efficient production and automation, increasing productivity and reducing labor requirements.

2. Transportation

Motors are crucial in transportation, powering vehicles such as cars, trucks, trains, ships, and aircraft. They provide the necessary propulsion for transportation systems, allowing people and goods to be transported over long distances quickly and efficiently.

B. Residential and Commercial Applications

1. Appliances

Motors are found in a wide range of household appliances, including refrigerators, washing machines, dishwashers, vacuum cleaners, and air conditioners. They drive the mechanical components of these appliances, enabling them to perform their intended functions.

2. HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems rely on motors to circulate air, control temperature, and maintain comfortable indoor environments. Motors power fans, blowers, and compressors in HVAC systems, ensuring proper air circulation and temperature regulation.

Advantages and Disadvantages of Motors

Like any technology, motors have their own set of advantages and disadvantages. Understanding these can help us make informed decisions regarding their use. Let's explore some of the key advantages and disadvantages:

A. Advantages

1. Efficiency

Motors are known for their high efficiency in converting energy into mechanical work. Electric motors, in particular, have excellent energy conversion rates and can be highly efficient when properly designed and operated. This efficiency leads to reduced energy consumption and lower operating costs.

2. Versatility

Motors are incredibly versatile, capable of powering a wide range of applications and devices. From small appliances to heavy industrial machinery, motors provide the necessary mechanical energy for various tasks. Their versatility makes them indispensable in numerous industries and daily life.

B. Disadvantages

1. Environmental Impact

Certain types of motors, such as internal combustion engines, contribute to environmental pollution. They release emissions, such as carbon dioxide and pollutants, into the atmosphere, which can contribute to climate change and air quality issues. Efforts are being made to develop cleaner and more sustainable motor technologies to mitigate these environmental impacts.

2. Maintenance Requirements

Motors, especially complex ones, require regular maintenance to ensure optimal performance and longevity. This can involve tasks such as lubrication, belt or filter replacement, and periodic inspections. Neglecting maintenance can lead to decreased efficiency, increased energy consumption, and potential breakdowns.

Future Trends in Motor Technology

Motor technology continues to evolve, driven by the need for increased efficiency, sustainability, and new applications. Here are a couple of notable future trends:

A. Electric Vehicles

Electric vehicles (EVs) are gaining popularity as a sustainable alternative to traditional internal combustion engine vehicles. The development of advanced battery technology has led to longer-range electric vehicles, reducing concerns about limited driving distance. Additionally, infrastructure development, such as the expansion of charging stations, is crucial for the widespread adoption of electric vehicles.

1. Advancements in Battery Technology

Efforts are underway to develop batteries with higher energy densities, faster charging capabilities, and longer lifespans. These advancements aim to address the limitations of current battery technology and further improve the performance and viability of electric vehicles.

2. Infrastructure Development

The expansion of charging infrastructure is essential for the widespread adoption of electric vehicles. Governments, businesses, and communities are investing in the development of charging networks to support the growing number of electric vehicles on the road.

B. Sustainable Energy Solutions

The integration of motors with sustainable energy sources is another significant trend in motor technology. This involves utilizing renewable energy sources, such as solar and wind power, to generate electricity for motors. It promotes the use of clean energy and reduces reliance on fossil fuels.

1. Renewable Energy Integration

Motors can be powered by electricity generated from renewable sources, contributing to a greener and more sustainable energy mix. By integrating motors with renewable energy infrastructure, such as solar panels or wind turbines, we can reduce greenhouse gas emissions and dependence on non-renewable resources.

2. Energy Efficiency Improvements

Continued research and development efforts focus on improving the energy efficiency of motors. More efficient motors result in reduced energy consumption, lower operating costs, and minimized environmental impact. Advanced motor designs, improved materials, and optimized control systems all contribute to enhanced energy efficiency.

Conclusion

Motors are integral to modern life, powering a vast array of devices and machines. From electric motors that drive appliances to internal combustion engines propelling vehicles, motors enable the smooth functioning of various industries and everyday activities. Understanding the different types of motors, their working principles, applications, advantages, and future trends is crucial for appreciating their significance and potential.

FAQs

1. What is the difference between an electric motor and an internal combustion engine?

Electric motors rely on electromagnetic induction to convert electrical energy into mechanical energy. They are commonly used in electric vehicles, appliances, and industrial machinery. On the other hand, internal combustion engines use the combustion of fuel to generate mechanical energy. They are prevalent in vehicles powered by gasoline or diesel.

2. Are motors used only in industrial applications?

No, motors are used in a wide range of applications, including industrial, residential, and commercial settings. They power appliances, HVAC systems, vehicles, manufacturing machinery, and more.

3. How do electric vehicles use motors?

Electric vehicles use electric motors to generate rotational motion, which drives the wheels and propels the vehicle forward. These motors are powered by electricity stored in batteries, allowing for emission-free transportation.

4. Can motors be powered by renewable energy sources?

Yes, motors can be powered by electricity generated from renewable energy sources such as solar, wind, or hydroelectric power. This promotes sustainable energy usage and reduces reliance on fossil fuels.

5. What are the main challenges in motor technology development?

Some of the main challenges in motor technology development include improving energy efficiency, reducing environmental impact, increasing power density, and addressing issues related to materials, heat dissipation, and cost-effectiveness. Ongoing research and innovation aim to overcome these challenges and drive the advancement of motor technology.

Thanks for Sharing your valuable Information. I really like this post.

ReplyDeleteIt is obvious that a new place of residence will require a new name plate design hanging outside their doors. name plate design

ReplyDelete