Induction Motor | 3 Phase Induction Motor | Squirrel Cage Induction Motor | What is Squirrel Cage Motor | AC Squirrel Cage Motor | 3 Phase Squirrel Cage Induction Motor | Application of Squirrel Cage Induction Motor | Power Factor of Squirrel Cage Induction Motor | Advantages of Squirrel Cage Induction Motor | Electric Motors

A squirrel cage induction motors are a type of AC electric motors that is commonly used in industrial and commercial applications. It is called a "squirrel cage" motor because the rotor, which is the rotating part of the motor, looks like a squirrel cage with conductive bars arranged in a circular shape.

The squirrel cage induction electric motors works by creating a rotating magnetic field in the stator, which is the stationary part of the motor. This magnetic field induces a current in the rotor, which causes the rotor to rotate. The conductive bars on the rotor are short-circuited together by end rings, which causes the rotor to act like a single conductor.

3 Phase Squirrel Cage Induction Motor is popular due to its simplicity, low cost, and rugged construction. It is also efficient, reliable, and requires little maintenance. These motors are commonly used in fans, blowers, pumps, compressors, conveyors, and other industrial machinery.

Speed of Squirrel Cage Induction Motor can be controlled

One disadvantage of the squirrel cage induction motor is that it cannot be easily speed-controlled like other AC motors, such as the wound rotor induction motor. However, variable frequency drives (VFDs) can be used to control the speed of squirrel cage induction motors by adjusting the frequency of the input power.

Industrial electric motors are broadly classified as induction

motors, direct current motors or synchronous motors.

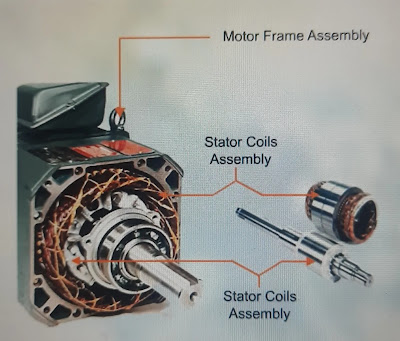

All motor types have the same four operating components: stator

(stationary windings), rotor (rotating windings), bearings, and frame

(enclosure).

Types of Electric Motors

1) Induction

Motor | 3 Phase Induction Motor

Induction motor is the most commonly used prime mover for various

equipments in industrial applications. In induction motors, the induced

magnetic field of the stator winding induces a current in the rotor. This

induced rotor current produces a second magnetic field, which tries to oppose

the stator magnetic field, and this causes the rotor to rotate.

These motors drive pumps, blowers and fans, compressors, conveyers

and production lines. The 3 phase induction motor has three windings each

connected to a separate phase of the power supply.

2) Direct-Current Motors

Direct-Current motors, as the name implies, use

direct-unidirectional, current. Direct current motors are used in special

applications- where high torque starting or where smooth acceleration over a

broad speed range is required.

3) Synchronous Motors

AC power is fed to the stator of the synchronous motor. The rotor

is fed by DC from a separate source. The rotor magnetic field locks onto the

stator rotating magnetic field and rotates at the same speed. The speed of the

rotor is a function of the supply frequency and the number of magnetic poles in

the stator.

While induction motors rotate with a slip, i.e., RPM is less than

the synchronous speed, the synchronous motor rotate with no slip, i.e., the RPM

is same as the synchronous speed governed by supply frequency and number of

poles. The slip energy is provided by the D.C. excitation power

Advantages of Synchronous motor

a. It’s a constant speed motor, speed being equal to synchronous speed from no load to full load.b. It has good efficiency, higher than induction motor.

c. It can be run as a motor and also as an alternator as per the requirement. Moreover it can be used as synchronous condenser.

Disadvantages of Synchronous motor

a. As a motor it is not self-starting type and it cannot be started on load.b. It requires both AC and DC supply.

c. Hunting is also produced in this motor.

Motor Characteristics

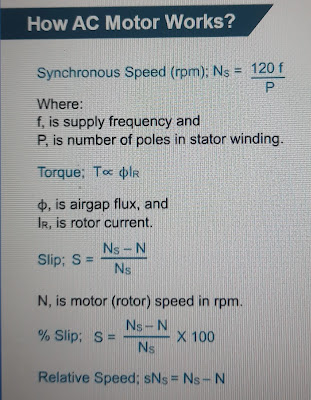

Motor Speed

The speed of a motor is the number of revolutions in a given time

frame, typically revolutions per minute (RPM). The speed of an AC motor depends

on the frequency of the input power and

the number of poles for which the motor is wound. The synchronous

speed in RPM is given by the following equation, where the frequency is in

hertz or cycles per second:

120 x Frequency

Synchronous Speed (RPM) = -----------------------------------

Motor’s Number of Poles

Common motors have synchronous speeds like 3000 / 1500 / 1000 /

750 / 600 / 500 / 375 RPM corresponding to no. of poles being 2, 4, 6, 8, 10,

12, 16 (always even) when given the mains frequency of 50 Hz.

The actual speed, with which the motor operates, will be less than

the synchronous speed. The difference between synchronous and full load speed

is called slip and is measured in percent.

(Synchronous Speed – Full Load Rated Speed)

Slip (%) = ------------------------------------------------------------------ x 100 Synchronous Speed

Slip (%) = ------------------------------------------------------------------ x 100 Synchronous Speed

As per equation stated above, the speed of an AC motor is

determined by the number of motor poles and by the input frequency. It can also

be seen that theoretically speed of an AC motor can be varied infinitely by

changing the frequency.

Manufacturer's guidelines should be referred for practical limits

to speed variation. With the addition of a Variable Frequency Drive (VFD), the

speed of the motor can be decreased as well as increased.

Power Factor of Squirrel Cage Induction Motor

The power factor of the motor is given as:

KW

COS Ф = ----------

KVA

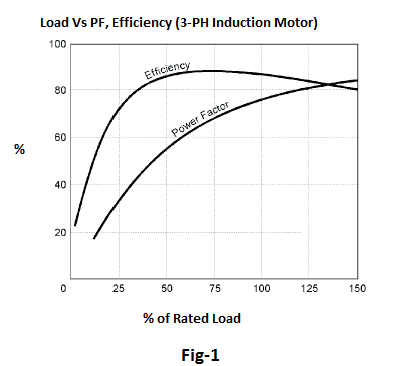

As

the load on the motor comes down, the magnitude of the active current

reduces.

However,

there is no corresponding reduction in the magnetizing current, which is

proportional to supply voltage with the result that the motor power factor

reduces, with a reduction in applied load. Induction motors, especially those

operating below their rated capacity, are the main reason for low power factor

in electric systems.

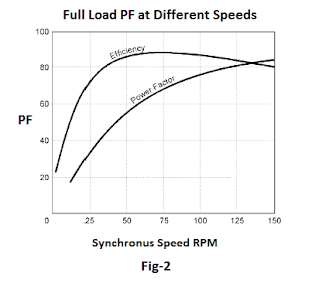

Motor Efficiency

Two important attributes relating to efficiency of electricity use

by A.C. Induction motors are efficiency (ŋ), defined as the ratio of the

mechanical energy delivered at the rotating shaft to the electrical energy

input at its terminals, and power factor (PF). Motors, like other inductive

loads, are characterized by power factors less than one. As a result, the total

current draw needed to deliver the same real power is higher than for a load

characterized by a higher PF. An important effect of operating with a PF less

than one is that resistance losses in wiring upstream

of the motor will be higher, since these are proportional to the

square of the current. Thus, both a high value for ŋ and a PF close to unity

are desired for efficient overall operation in a plant.

Squirrel cage motors are normally more efficient than slip-ring

motors, and higher-speed motors are normally more efficient than lower-speed

motors.

Efficiency is also a function of motor temperature. Totally-enclosed, fan-cooled (TEFC)

motors are more efficient than screen protected, drip-proof (SPDP) motors.

Also, as with most equipment, motor efficiency increases with the rated

capacity.

The

efficiency of a motor is determined by intrinsic losses that can be reduced

only by changes in motor design. Intrinsic losses are of two types: fixed

losses - independent of motor load, and variable losses - dependent on load.

Fixed

losses consist of

magnetic core losses and friction and windage losses. Magnetic core losses

(sometimes called iron losses) consist of eddy current and hysteresis losses in

the stator. It vary with the core material and geometry and with input voltage.

Friction

and windage losses are caused by friction in the bearings of the motor and

aerodynamic losses associated with the ventilation fan and other rotating

parts.

Variable

losses consist of

resistance losses in the stator and in the rotor and miscellaneous stray

losses. Resistance to current flow in the stator and rotor result in heat

generation that is proportional to the resistance of the material and the

square of the current (I2R).

The primary technical consideration defining the motor choice for

any particular application is the torque required by the load, especially the

relationship between the maximum torque generated by the motor (break-down

torque) and the torque requirements for start-up (locked rotor torque) and

during acceleration periods.

The duty / load cycle determines the thermal loading on the motor.

One consideration with totally enclosed fan cooled (TEFC) motors is that the

cooling may be insufficient when the motor is operated at speeds below its

rated value.

Ambient operating conditions affect motor choice; special motor

designs are available for corrosive or dusty atmospheres, high temperatures,

restricted physical space, etc.

An estimate of the switching frequency (usually dictated by the

process), whether automatic or manually controlled, can help in selecting the appropriate

motor for the duty cycle.

The demand a motor will place on the balance of the plant

electrical system is another consideration

- if the load variations are large, for example as a result of

frequent starts and stops of large components like compressors, the resulting

large voltage drops could be detrimental to other equipment.

Reliability

is of prime importance - in many cases, however, designers and process

engineers seeking reliability will grossly oversize equipment, leading to

sub-optimal energy performance.

Good

knowledge of process parameters and a better understanding of the plant power

system can aid in reducing over sizing with no loss of reliability.

Inventory

is another consideration - Many large industries use standard equipment, which

can be easily serviced or replaced, thereby reducing the stock of spare parts

that must be maintained and minimizing shut-down time. This practice affects

the choice of motors that might provide better energy performance in specific

applications. Shorter lead times for securing Individual

motors from suppliers would help reduce the need for this practice.

Price

is another issue - Many users are first-cost sensitive, leading to the purchase

of less expensive motors that may be more costly on a lifecycle basis because

of lower efficiency. For example, energy efficient motors or other specially

designed motors typically save within a few years an amount of money equal to

several times the incremental cost for an energy efficient motor, over a

standard-efficiency motor. Few of salient selection issues are given below:

•

In the selection process, the power drawn at 75 % of loading can be a

meaningful indicator of energy efficiency.

•

Reactive power drawn (kVAR) by the motor.

•

It would be prudent for buyers to procure motors based on test certificates

rather than labeled values.

•

The cost benefits can be worked out on the basis of premium required for high

efficiency’s. worth of annual savings.

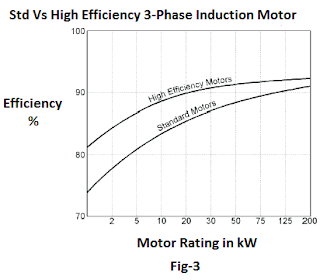

Energy-Efficient Motors

Energy-efficient motors (EEM) are the ones in which, design

improvements are incorporated specifically to increase operating efficiency

over motors of standard design (see Figure 3)

Design improvements focus on reducing intrinsic motor losses. Improvements include the use of lower-loss silicon steel, a longer core (to increase active material), thicker wires (to reduce resistance), thinner laminations, smaller air gap between stator and rotor, copper instead of aluminum bars in the rotor, superior bearings and a smaller fan, etc.

Design improvements focus on reducing intrinsic motor losses. Improvements include the use of lower-loss silicon steel, a longer core (to increase active material), thicker wires (to reduce resistance), thinner laminations, smaller air gap between stator and rotor, copper instead of aluminum bars in the rotor, superior bearings and a smaller fan, etc.

Energy-efficient motors now available operate with

efficiencies that are typically 3 to 4 percentage points higher than standard

motors. In keeping with the stipulations of the BIS, energy-efficient motors

are designed to operate without loss in efficiency at loads between 75 %and 100

% of rated capacity. This may result in major benefits in varying load

applications. The power factor is about the same or may be higher than for

standard motors. Furthermore, energy-efficient motors have lower operating temperatures and noise

levels, greater ability to accelerate higher-inertia loads, and are less

affected by supply voltage fluctuations. Measures adopted for energy efficiency

address each loss specifically as under:

Stator and Rotor I2R Losses

These

losses are major losses and typically account for 55% to 60% of the total

losses. I2R losses are heating losses resulting from current passing through

stator and rotor conductors. I2Rlosses are the function of a conductor

resistance, the square of current. Resistance of conductors a function of

conductor material, length and cross sectional area. The suitable selection of

copper conductor size will reduce the resistance. Reducing the motor current is

most readily accomplished by decreasing the magnetizing component of current.

This involves lowering the operating flux density and possible shortening of

air gap. Rotor I2R losses are a function of the rotor conductors (usually

aluminium) and the rotor slip. Utilisation of copper conductors will reduce the

winding resistance. Motor operation closer to synchronous speed will also

reduce rotor I2R losses.

Core Losses

Core

losses are those found in the stator-rotor magnetic steel and are due to

hysterisis effect and eddy current effect during 50 Hz magnetization of the

core material. These losses are independent of load and account for 20 – 25 %

of the total losses.

The

hysterisis losses which are a function of flux density, are be reduced by

utilizing low loss grade of silicon steel laminations. The reduction of flux

density is achieved by suitable increase in the core length of stator and

rotor. Eddy current losses are generated by circulating current within the core

steel laminations. These are reduced by using thinner laminations.

Friction and Windage Losses

Friction and windage losses results from bearing friction, windage and

circulating air through the motor and account for 8 – 12 % of total losses.

These losses are independent of load. The reduction in heat generated by stator

and rotor losses permit the use of smaller fan. The windage losses also reduce

with the diameter of fan leading to reduction in windage losses.

Stray Load-Losses

These

losses vary according to square of the load current and are caused by leakage

flux induced by load currents in the lamination and account for 4 to 5 % of

total losses. These losses are reduced by careful selection of slot numbers,

tooth/slot geometry and air gap.

Energy efficient motors cover a wide range of ratings and the full

load efficiencies are higher by 3 to 7 %. The mounting dimensions are also

maintained as per IS1231 to enable easy replacement.

As

a result of the modifications to improve performance, the costs of

energy-efficient motors are higher than those of standard motors. The higher

cost will often be paid back rapidly in saved operating costs, particularly in

new applications or end-of-life motor replacements. In cases where existing

motors have not reached the end of their useful life, the economics will be less

clearly positive. Because the favorable economics of energy-efficient motors

are based on savings in operating costs, there may be certain cases, which are

generally economically ill suited to energy efficient motors. These include

highly intermittent duty or special torque applications such as hoists and

cranes, traction drives, punch presses, machine tools, and centrifuges. In

addition, energy, efficient designs of multi-speed motors are generally not

available. Furthermore, energy-efficient motors are not yet available for many

special applications, e.g. for flameproof operation in oil field or fire pumps

or for very low speed applications (below 750 rpm). Also, most energy-efficient

motors produced today are designed only for continuous duty cycle operation.

Power Losses

|

Improvement of Efficiency

|

Stray Load Loss

|

Use of optimized design and strict quality

control procedures minimizes stray

|

Rotor I2R

|

Use of larger rotor conductor bars

increases size of cross section, lowering conductor resistance (R) and losses

due to current flow (I).

|

Friction & Windage

|

Use of low loss fan design reduces losses

due to air movement.

|

Iron:

|

Use of thinner gauge, lower loss core

steel reduces eddy current losses. Longer core adds more steel to the design,

which reduces losses due to lower operating flux densities.

|

Stator I2R

|

Use of more copper and larger

conductors increases cross sectional area of stator windings. This lowers

resistance (R) of the windings and reduces losses due to current flow (I).

|

Factors Affecting Energy Efficiency & Minimising Motor Losses in Operation

a) Power Supply Quality

Motor

performance is affected considerably by the quality of input power, that is the

actual volts and frequency available at motor terminals: rated values as well

as voltage and frequency variations and voltage unbalance across the three

phases.

The

BIS standards specify that a motor should be capable of delivering its rated

output with a voltage variation of +/- 6 % and frequency variation of +/- 3 %.

Voltage

unbalance, the condition where the voltages in the three phases are not equal,

can be still more detrimental to motor performance and motor life. Unbalance

typically occurs as result of supplying single-phase loads disproportionately

from one of the phases. It can also result from the use of different sizes of

cables in the distribution system.

Ø

Load

end PF improvement by providing matching PF capacitors

Ø

Transformer

tap changing required if continuous and consistent low voltage situation

Ø

Minimising

line /cable voltage drops from LT PDB / MCC to motor terminals

To minimize

voltage unbalance include:

i)

Balancing all single phase loads equally among all the three phases

ii)

Segregating any single phase loads which disturb the load balance and feed them

from a separate line / transformer

Motor Loading

Measuring

Load

% Loading

of the motor can be estimated by the following relation:

% loading =

Input power drawn by the motor (kW) at existing load x 100

(Name plate

full load kW rating / name plate full load motor efficiency)

or % loading =

Input power drawn by the motor (kW) at existing load x 100

√3 x kV x I

CosØ

• Never

assume power factor

• Loading

should not be estimated as the ratio of currents.

Reducing Under loading

Probably

the most common practice contributing to sub-optimal motor efficiency is that

of under-loading. Under-loading results in lower efficiency and power factor,

and higher-than-necessary first cost for the motor and related control

equipment. Under-loading is common for several reasons.

Original equipment manufacturers tend to use a large safety factor in motors they select. Under-loading of the motor may also occur from under-utilisation of the equipment. For example, machine tool equipment manufacturers provide for a motor rated for the full capacity load of the equipment ex. depth of cut in a lathe machine. The user may need this full capacity rarely, resulting in under-loaded operation most of the time. Another common reason for under loading is selection of a larger motor to enable the output to be maintained at the desired level even when input voltages are abnormally low. Finally, under-loading also results from selecting a large motor for an application requiring high starting torque where a special motor, designed for high torque, would have been suitable.

Original equipment manufacturers tend to use a large safety factor in motors they select. Under-loading of the motor may also occur from under-utilisation of the equipment. For example, machine tool equipment manufacturers provide for a motor rated for the full capacity load of the equipment ex. depth of cut in a lathe machine. The user may need this full capacity rarely, resulting in under-loaded operation most of the time. Another common reason for under loading is selection of a larger motor to enable the output to be maintained at the desired level even when input voltages are abnormally low. Finally, under-loading also results from selecting a large motor for an application requiring high starting torque where a special motor, designed for high torque, would have been suitable.

A careful evaluation of the load would determine the capacity of the motor that should be selected. Another aspect to consider is the incremental gain in efficiency achievable by changing the motor. Larger motors have inherently higher rated efficiencies than smaller motors. Therefore, the replacement of motors operating at 60 – 70 % of capacity or higher is generally not recommended.

However, there are no rigid rules governing motor selection; the savings potential needs to be evaluated on a case-to-case basis. When downsizing, it may be preferable to select an energy-efficient motor, the efficiency of which may be higher than that of a standard motor of higher capacity.

For motors, which consistently operate at loads below 40 % of rated capacity, an inexpensive and effective measure might be to operate in star mode. A change from the standard delta operation to star operation involves re-configuring the wiring of the three phases of power input at the terminal box.

Operating

in the star mode leads to a voltage reduction by a factor of '√3'. Motor is

electrically downsized by star mode operation, but performance characteristics

as a function of load remain unchanged. Thus, full-load operation in star mode

gives higher efficiency and power factor than partial load operation in the

delta mode. However, motor operation in the star mode is possible only for

applications where the torque-to-speed requirement is lower at reduced load.

As speed of the motor reduces in star mode this option may be avoided in case the motor is connected to a production facility whose output is related to the motor speed. For applications with high initial torque and low running torque needs, Del-Star starters are also available in market, which help in load following de-rating of electric motors after initial start-up.

Sizing to Variable Load

Industrial

motors frequently operate under varying load conditions due to process

requirements.

A common practice in cases where such variable-loads are found is to select a motor based on the highest anticipated load. In many instances, an alternative approach is typically less costly, more efficient, and provides equally satisfactory operation. With this approach, the optimum rating for the motor is selected on the basis of the load duration curve for the particular application.

Thus, rather than selecting a motor of high rating that would operate at full capacity for only a short period, a motor would be selected with a rating slightly lower than the peak anticipated load and would operate at overload for a short period of time. Since operating within the thermal capacity of the motor insulation is of greatest concern in a motor operating at higher than its rated load, the motor rating is selected as that which would result in the same temperature rise under continuous

full-load

operation as the weighted average temperature rise over the actual operating

cycle.

Under extreme load changes, e.g. frequent starts / stops, or high inertial loads, this method of calculating the motor rating is unsuitable since it would underestimate the heating that would occur where loads vary substantially with time, in addition to proper motor sizing, the control strategy employed can have a significant impact on motor electricity use.

Traditionally, mechanical means (e.g. throttle valves in piping systems) have been used when lower output is required. More efficient speed control mechanisms include multi-speed motors, eddy-current couplings, fluid couplings, and solid-state electronic variable speed drives.

Power Factor Correction

As noted

earlier, induction motors are characterized by power factors less than unity,

leading to lower overall efficiency (and higher overall operating cost)

associated with a plant's electrical system. Capacitors connected in parallel

(shunted) with the motor are typically used to improve the power factor. The

impacts of PF correction include reduced kVA demand (and hence reduced utility

demand charges), reduced I2R losses in cables upstream of the capacitor (and

hence reduced energy charges), reduced voltage drop in the cables (leading to

improved voltage regulation), and an increase in the overall efficiency of the

plant electrical system.

It should

be noted that PF capacitor improves power factor from the point of installation

back to the generating side. It means that, if a PF capacitor is installed at

the starter terminals of the motor, it won't improve the operating PF of the

motor, but the PF from starter terminals to the power generating side will

improve, i.e., the benefits of PF would be only on upstream side.

The size of capacitor required for a particular motor depends upon the no-load reactive kVA(kVAR) drawn by the motor, which can be determined only from no-load testing of the motor.

The size of capacitor required for a particular motor depends upon the no-load reactive kVA(kVAR) drawn by the motor, which can be determined only from no-load testing of the motor.

Motor Rating (HP)

|

Motor Speed / Capacitor rating(kVAr)

|

|||||

3000

|

1500

|

1000

|

750

|

600

|

500

|

|

5

|

2

|

2

|

2

|

3

|

3

|

3

|

7.5

|

2

|

2

|

3

|

3

|

4

|

4

|

10

|

3

|

3

|

4

|

5

|

5

|

6

|

15

|

3

|

4

|

5

|

7

|

7

|

7

|

20

|

5

|

6

|

7

|

8

|

9

|

10

|

25

|

6

|

7

|

8

|

9

|

9

|

12

|

30

|

7

|

8

|

9

|

10

|

10

|

15

|

40

|

9

|

10

|

12

|

15

|

16

|

20

|

50

|

10

|

12

|

15

|

18

|

20

|

22

|

60

|

12

|

14

|

15

|

20

|

22

|

25

|

75

|

15

|

16

|

20

|

22

|

25

|

30

|

100

|

20

|

22

|

25

|

26

|

32

|

35

|

125

|

25

|

26

|

30

|

32

|

35

|

40

|

150

|

30

|

32

|

35

|

40

|

45

|

50

|

200

|

40

|

45

|

45

|

50

|

55

|

60

|

250

|

45

|

50

|

50

|

60

|

65

|

70

|

In general,

the capacitor is then selected to not exceed 90 % of the no-load kVAR of the

motor.

(Higher

capacitors could result in over-voltages and motor burn-outs). Alternatively,

typical power

factors of standard motors can provide the basis for conservative estimates of

capacitor ratings to use for different size motors. The capacitor rating for

power connection by direct connection to induction motors is shown in above Table

From the above table, it may be noted that required capacitive kVAr increases with decrease in speed of the motor, as the magnetizing current requirement of a low speed motor is more in comparison to the high speed motor for the same HP of the motor. Since a reduction in line current, and associated energy efficiency gains, are reflected backwards from the point of application of the Capacitor, the maximum improvement in overall system efficiency is achieved when the capacitor is connected across the motor terminals, as compared to somewhere further upstream in the plant’s electrical system.

However,

economies of scale associated with the cost of capacitors and the labor

required

to install them will place an economic limit on the lowest desirable capacitor

size.

Age factor

Most

motor cores in are manufactured from silicon steel or de-carbonized cold-rolled

steel, the electrical properties of which do not change measurably with age.

However, poor maintenance (inadequate lubrication of bearings, insufficient

cleaning of air cooling passages, etc.) can cause deterioration in motor

efficiency over time. Ambient conditions can also have a detrimental effect on

motor performance. For example, excessively high temperatures, high dust

loading, corrosive atmosphere, and humidity can impair insulation properties;

mechanical stresses due to load cycling can

lead to misalignment. However, with adequate care, motor performance can be

maintained.

Effects of Burnt Motor Rewinding on Energy Efficiency

In

industry it is common practice to rewind burnt-out motors. The population of

rewound

Motors

in some industries exceed 40-50 % of the total population. Careful rewinding

can sometimes maintain motor efficiency at previous levels, but in most cases,

losses in efficiency result.

Rewinding

can affect a number of factors that contribute to deteriorate motor efficiency:

winding and slot design, winding material, insulation performance, and

operating temperature.

e.g.

Generally problem occurs when heat is applied to strip old windings: the

insulation between laminations can be damaged, thereby increasing eddy current

losses. A change in the air gap may affect power factor and output torque.

However,

if proper measures are taken, motor efficiency can be maintained, and in some Cases

increased, after rewinding.

Efficiency

can be improved by changing the winding design, though the power factor could

be affected in the process. Using wires of greater cross section, slot size

permitting, would reduce stator losses thereby increasing efficiency. However,

it is generally recommended that the original design of the motor be preserved

during the rewind, unless there are specific, load-related reasons for

redesign.

The impact

of rewinding on motor efficiency and power factor can be easily assessed if the

no-load losses of a motor are known before and after rewinding. Maintaining

documentation of no-load losses and no-load speed from the time of purchase of

each motor can facilitate assessing this impact.

e.g.

comparison of no load current and stator resistance per phase of a rewound

motor with

the original no-load current and stator resistance at the same voltage can be

one of the indicators to assess the efficiency of rewinding.

Applications of Squirrel Cage Induction Motor

- Industrial Applications

- Pumps

- Compressors

- Fans

- Conveyors

- Mixers

- Centrifugal machines

- Cranes and hoists

- Machine tools

Commercial Applications

- Elevators

- Escalators

- Refrigeration and air conditioning systems

Domestic Applications

- Washing machines

- Vacuum cleaners

- Food processors

- Mixers and grinders

Advancements in Squirrel Cage Induction Motor Technology

- Improvements in rotor design

- Use of soft starters and variable frequency drives

- Adoption of energy-efficient motors

Selection Criteria for Squirrel Cage Induction Motors

- Power requirements

- Speed requirements

- Duty cycle

- Starting torque

- Environment

Maintenance of Squirrel Cage Induction Motor

Lubrication

Bearing replacement

Inspection of rotor and stator

Regular testing

Advantages of Squirrel Cage Induction Motor

Low cost

Low maintenance

Robust construction

High reliability

Wide range of power ratings

Summary

Squirrel cage induction motors are an essential part of many industries, and their applications are vast. Advancements in technology have made them even more efficient, reliable, and durable. Selecting the right motor for your application and maintaining it properly can help increase the lifespan of the motor and reduce downtime.

FAQs

Q: What is the difference between a squirrel cage induction motor and a wound rotor induction motor?

A: The main difference between a squirrel cage induction motor and a wound rotor induction motor is in the type of rotor they use. A squirrel cage motor uses a rotor with conductive bars, typically made of copper or aluminum, arranged in a cage-like structure. A wound rotor motor, on the other hand, uses a rotor with a set of windings that are connected to slip rings, allowing external resistors or other devices to be used for controlling the motor.

Q: What is the role of soft starters in squirrel cage induction motors?

A: Soft starters are used to limit the inrush current and reduce the starting torque of a squirrel cage induction motor. This helps to prevent damage to the motor and the connected equipment, and also reduces stress on the power supply. Soft starters achieve this by controlling the voltage and frequency of the motor during the starting phase.

Q: Can squirrel cage induction motors be used in hazardous environments?

A: Yes, squirrel cage induction motors can be used in hazardous environments, provided they are properly protected and designed for the specific conditions. This may involve the use of explosion-proof enclosures, special insulation, or other safety features.

Q: How do I determine the correct size of squirrel cage induction motor for my application?

A: The correct size of squirrel cage induction motor for a specific application depends on a range of factors, including the required torque, speed, power, and duty cycle. Other factors that need to be considered include the load characteristics, environmental conditions, and safety requirements. Consulting with a qualified motor supplier or engineer can help determine the correct motor size for a specific application.

Q: How often should I perform maintenance on my squirrel cage induction motor?

A: The frequency of maintenance for a squirrel cage induction motor depends on several factors, including the operating conditions, duty cycle, and load characteristics. In general, regular inspections and testing should be performed to ensure the motor is operating correctly and efficiently. Lubrication, bearing replacement, and other maintenance tasks should be performed according to the manufacturer's recommendations or as needed based on the specific operating conditions.

Hello, I read your blog, and you have explained it very well. Thanks for sharing your knowledge with us. Filter Press Manufacturers

ReplyDelete