HVAC | HVAC System Diagram | HVAC Full Form | HVAC system working principle | What is a HVAC System | HVAC System Diagram | HVAC Meaning | HVAC FAQ

When it comes to keeping your home or business comfortable, an HVAC system is an essential piece of equipment. HVAC stands for Heating, Ventilation, and Air Conditioning, and it is responsible for controlling the temperature, humidity, and air quality in a given space. In this article, we will be discussing the components of an HVAC system: the heating system.HVAC system is widely used in Malls, Industrial plants, Movie multiplexes.

HVAC Full Form

Heating, Ventilation and Air Conditioning (HVAC) and refrigeration system transfers the heat energy from or to the products, or building environment. Energy in form of electricity or heat is used to power mechanical equipment designed to transfer heat from a colder, low-energy level to a warmer, high-energy level.

Refrigeration deals with the transfer of heat from a low temperature level at the heat source to a high temperature level at the heat sink by using a low boiling refrigerant.

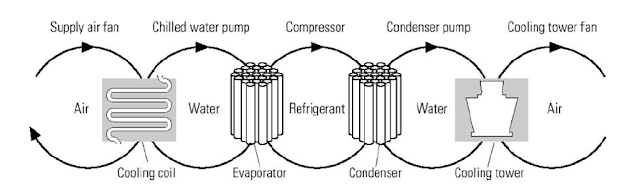

There are several heat transfer loops in refrigeration system as described below:

|

| Heat Transfer Loop |

1. Indoor air loop- In the leftmost loop, indoor air is driven by the supply air fan through a cooling coil, where it transfers its heat to chilled water. The cool air then cools the building space.

2. Chilled water loop- Driven by the chilled water pump, water returns from the cooling coil to the chiller’s evaporator to be re-cooled.

3. Refrigerant loop- Using a phase-change refrigerant, the chiller’s compressor pumps heat from the chilled water to the condenser water.

4. Condenser water loop- Water absorbs heat from the chiller’s condenser, and the condenser water pump sends it to the cooling tower.

5. Cooling tower loop- The cooling tower’s fan drives air across an open flow of the hot condenser water, transferring the heat to the outdoors.

Air-Conditioning Systems

Refrigeration Systems (for processes)

Small capacity modular units of direct expansion type similar to domestic refrigerators, small capacity refrigeration units.

Centralized chilled water plants with chilled water as a secondary coolant for temperature range over 5°C typically. They can also be used for ice bank formation.

Brine plants, which use brines as lower temperature, secondary coolant, for typically sub zero temperature applications, which come as modular unit capacities as well as large centralized plant capacities.

The plant capacities upto 50 TR are usually considered as small capacity, 50 – 250 TR as medium capacity and over 250 TR as large capacity units.

A large industry may have a bank of such units, often with common chilled water pumps, condenser water pumps, cooling towers, as an off site utility.

The same industry may also have two or three levels of refrigeration & air conditioning such as:

Comfort air conditioning (20° – 25° C)

Chilled water system (8° – 10° C)

Brine system (sub-zero applications)

Two principle types of refrigeration plants found in industrial use are: Vapour Compression, Refrigeration (VCR) and Vapour Absorption Refrigeration (VAR). VCR uses mechanical energy as the driving force for refrigeration, while VAR uses thermal energy as the driving force for refrigeration.

Types of Refrigeration System

Vapour Compression Refrigeration Heat flows naturally from a hot to a colder body. In refrigeration system the opposite must occur i.e. heat flows from a cold to a hotter body. This is achieved by using a substance called a refrigerant, which absorbs heat and hence boils or evaporates at a low pressure to form a gas. This gas is then compressed to a higher pressure, such that it transfers the heat it has gained to ambient air or water and turns back (condenses) into a liquid. In this way heat is absorbed, or removed, from a low temperature source and transferred to a higher temperature source.

Alternative Refrigerants for Vapour Compression Systems

The use of CFCs is now beginning to be phased out due to their damaging impact on the protective tropospheric ozone layer around the earth. The Montreal Protocol of 1987 and the subsequent Copenhagen agreement of 1992 mandate a reduction in the production of ozone depleting Chlorinated Fluorocarbon (CFC) refrigerants in a phased manner, with an eventual stop to all production by the year 1996. In response, the refrigeration industry has developed two alternative refrigerants; one based on Hydrochloro Fluorocarbon (HCFC), and another based on Hydro Fluorocarbon (HFC). The HCFCs have a 2 to 10% ozone depleting potential as compared to CFCs and also, they have an atmospheric lifetime between 2 to 25 years as compared to 100 or more years for CFCs (Brandt, 1992). However, even HCFCs are mandated to be phased out by 2005, and only the chlorine free (zero ozone depletion)HFCs would be acceptable.

Until now, only one HFC based refrigerant, HFC 134a, has been developed. HCFCs are comparatively simpler to produce and the three refrigerants 22, 123, and 124 have been developed.

The use of HFCs and HCFCs results in slightly lower efficiencies as compared to CFCs, but this may change with increasing efforts being made to replace CFCs.

Absorption Refrigeration

The absorption chiller is a machine, which produces chilled water by using heat such as steam, hot water, gas, oil etc. Chilled water is produced by the principle that liquid (refrigerant), which evaporates at low temperature, absorbs heat from surrounding when it evaporates. Pure water is used as refrigerant and lithium bromide solution is used as absorbent

Evaporator

The refrigerant (water) evaporates at around 4°C under the high vacuum condition of 754 mm Hg in the evaporator.When the refrigerant (water) evaporates,the latent heat of vaporization takes the heat from incoming chilled water.

This latent heat of vaporization can cool the chilled water which runs into the heat exchanger tubes in the evaporator by transfer of heat to the refrigerant (water).

Absorber

In order to keep evaporating, the refrigerant vapor must be discharged from the evaporator and refrigerant (water) must be supplied. The refrigerant vapor is absorbed into lithium bromide solution which is convenient to absorb the refrigerant vapor in the absorber. The heat generated in the

absorption process is led out of system by cooling water continually. The absorption also maintains the vacuum

inside the evaporator.

High pressure Absorber

As lithium bromide solution is diluted, the effect to absorb the refrigerant vapor reduces. In order to keepabsorption process, the diluted lithium bromide solution must be made

concentrated lithium bromide.

Absorption chiller is provided with the solution concentrating system by the heating media such as steam, hot water, gas, oil, which performs such function is called generator.

The concentrated solution flows into the absorber and absorbs the refrigerant vapor again.

Condensor

In order to carryout above works continually and to make complete cycle,the following two functions arerequired.

(1) To concentrate and liquefy the evaporated refrigerant vapor,which is generated in the high pressure generator.

(2) To supply the condensed water tothe evaporator as refrigerant (water) For this function, condenser is installed.

Evaporative Cooling

There are occasions where air conditioning, which stipulates control of humidity up to 50 % for human comfort or for process, can be replaced by a much cheaper and less energy intensive evaporative cooling.

The concept is very simple and is the same as that used in a cooling tower. Air is brought in close contact with water to cool it to a temperature close to the wet bulb temperature.

The cool air can be used for comfort or process cooling. The disadvantage is that the air is rich in moisture. Nevertheless, it is an extremely efficient means of cooling at very low cost.

Large commercial systems employ cellulose filled pads over which water is sprayed. The temperature can be controlled by controlling the airflow and the water circulation rate. The possibility of evaporative cooling is especially attractive for comfort cooling in dry regions. This principle is practiced in textile industries for certain processes.

Common Refrigerants and Properties

A variety of refrigerants are used in vapor compression systems. The choice of fluid is determined largely by the cooling temperature required. Commonly used refrigerants are in the family of chlorinated fluorocarbons (CFCs, also called Freons): R-11, R-12, R-21, R-22 and R-502.

Refrigeration Plants Performance Assessment

● The cooling effect produced is quantified as tons of refrigeration.(TR).

1 TR of refrigeration = 3024 kCal/hr heat rejected.

The refrigeration TR is assessed as

TR = Q x Cp x (Ti – To) / 3024

Where Q is mass flow rate of coolant in kg/hr

Cp is coolant specific heat in kCal /kg deg C

Ti is inlet, temperature of coolant to evaporator (chiller) in °C

To is outlet temperature of coolant from evaporator (chiller) in °C.

The above TR is also called as chiller tonnage.

The specific power consumption kW/TR is a useful indicator of the performance of refrigeration system. By measuring refrigeration duty performed in TR and the kiloWatt inputs, kW/TR is used as a reference energy performance indicator.

In a centralized chilled water system, apart from the compressor unit, power is also consumed by the chilled water (secondary) coolant pump as well condenser water

(for heat rejection to cooling tower) pump and cooling tower fan in the cooling tower.

Effectively, the overall energy consumption would be towards:

• Compressor kW

• Chilled water pump kW

• Condenser water pump kW

• Cooling tower fan kW, for induced / forced draft towers

Thanks for sharing this informative post!

ReplyDeleteindustrial dryers & ovens

industrial-chillers

rain chambers

dust chambers

Thank you Cozy for the efcient recommendation for HVAC, we are really happy about our decisions and we got a great deal on commercial HVAC Toronto

ReplyDeleteThat's an interesting news thanks for sharing the information. It really helps many peoples. R22 refrigerant

ReplyDeleteThis comment has been removed by a blog administrator.

ReplyDeleteWhen any appliance starts making noises it's never made before, especially if the noises continue for a period of time or even get worse, you can benefit from calling in an appliance repair technician. Your air conditioneris no exception. Toronto Air Conditioning Repair

ReplyDeleteThis is a good common sense Blog. Very helpful to one who is just finding the resources about this part. It will certainly help educate me. single zone mini split

ReplyDeleteExcellent tips. Really useful stuff .Never had an idea about this, will look for more of such informative posts from your side... Good job...Keep it up AC coil cleaning San Antonio

ReplyDelete