Lockout | Lockout Tagout | Steps To Lockout Tagout | Steps Of Lockout Tagout | Lockout Tagout Kit | Lockout Tagout Devices | Lockout Tagout Definition | Basics Of Lockout Tagout

Workplace safety is paramount for the well-being of employees and the smooth operation of businesses. One critical safety practice is Lockout Tagout (LOTO), a set of procedures used to control hazardous energy during maintenance and servicing of machinery or equipment. In this article, we will delve into the concept of Lockout Tagout, its importance, legal requirements, implementation, challenges, best practices, and more.

What is Lockout Tagout (LOTO)?

Lockout Tagout, often abbreviated as LOTO, is a safety procedure used to ensure that hazardous energy sources are isolated or controlled during maintenance, repair, or cleaning activities. It involves the use of locks, tags, and other safety devices to prevent the accidental start-up of machinery or equipment that could endanger workers' lives.

Why is Lockout Tagout important?

The importance of Lockout Tagout cannot be overstated when it comes to workplace safety. By implementing LOTO procedures, employers can effectively protect their employees from hazardous energy sources, such as electrical, mechanical, hydraulic, or pneumatic energy. LOTO helps prevent accidental injuries, electrocutions, amputations, and fatalities caused by the unexpected release of stored energy.

Legal Requirements and Standards for Lockout Tagout

Various regulatory bodies and standards organizations have established guidelines and regulations for Lockout Tagout procedures. The Occupational Safety and Health Administration (OSHA) in the United States, for instance, requires employers to adhere to the Control of Hazardous Energy standard (29 CFR 1910.147) to protect workers. Similarly, international standards such as ISO 45001 provide guidelines for implementing effective Lockout Tagout programs.

Components of a Lockout Tagout Program

A comprehensive Lockout Tagout program consists of several key components. These include energy control procedures, lockout devices, tags, employee training, periodic inspections, and documentation. Each component plays a vital role in ensuring the safe execution of maintenance tasks and preventing accidents.

Step-by-Step Lockout Tagout Procedure

To implement a successful Lockout Tagout procedure, it is essential to follow a systematic approach. The step-by-step process typically involves preparation, equipment shutdown, equipment isolation, lockout device installation, verification of isolation, release of stored energy, task completion, and equipment restoration. Adhering to this procedure is crucial for minimizing risks and maintaining worker safety.

Benefits of Implementing Lockout Tagout

Implementing a robust Lockout Tagout program yields numerous benefits for both employers and employees. It helps reduce workplace accidents, lowers insurance costs, improves compliance with safety regulations, enhances productivity by minimizing downtime, and promotes a culture of safety and responsibility among workers. Ultimately, a strong emphasis on Lockout Tagout leads to a safer and more efficient working environment.

Common Challenges and Solutions

While Lockout Tagout procedures are crucial, implementing them effectively can pose challenges. Some common hurdles include lack of awareness, inadequate training, employee negligence, language barriers, and difficulties in coordinating multiple maintenance tasks. To overcome these challenges, employers can prioritize education and training, streamline communication, provide multilingual resources, and foster a culture of safety through regular reinforcement and incentives.

Training and Education on Lockout Tagout

Proper training and education are fundamental to the successful implementation of Lockout Tagout procedures. Employers must ensure that workers receive comprehensive training on the importance of LOTO, the procedures involved, the proper use of lockout devices and tags, and the potential risks associated with hazardous energy. Ongoing education and periodic refresher courses also play a vital role in maintaining a high level of safety awareness among employees.

Lockout Tagout Best Practices

To optimize the effectiveness of Lockout Tagout programs, following best practices is crucial. These practices include conducting thorough risk assessments, developing clear and concise procedures, implementing standardized lockout devices and tags, establishing a robust communication system, performing regular inspections, and continuously improving the program based on feedback and lessons learned.

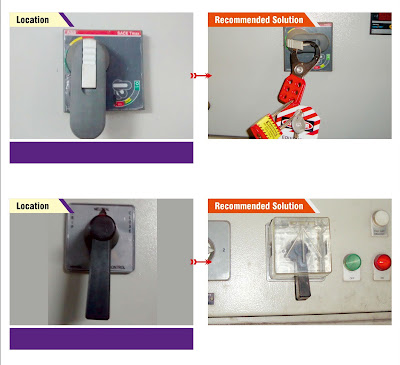

Lockout Tagout Devices and Equipment

Lockout Tagout procedures require the use of specialized devices and equipment to isolate energy sources effectively. These include lockout hasps, padlocks, circuit breakers, valve lockouts, electrical plug lockouts, and tagout devices. Each device serves a specific purpose and ensures the safe isolation of energy during maintenance or repair activities

General Factory Requirement

1) Isolation Facility

The plant and equipment shall be so constructed and maintained as to enable quick isolation of plant or equipment, with appropriate indication.

2) Permit to Work or Work Permit (PTW)

All parts of plant or machinery or equipment on which PTW system is carried out, shall remain isolated throughout the period and the place of work including the parts of plant, machinery shall be rendered safe by cleaning, purging, washing, etc.

LOTO Keeper - A qualified and Authorised person who is specifically appointed with overall responsibility for a Lockout/Tagout to place

Loto keeper will keep all hazardous energy sources under Lockout /Tagout and to account for all persons working on the job or task

Hazardous Energies

Hydraulic, Pneumatic, Mechanical, Electrical, Thermal

Chemical, Stored Energy Hazards (e.g.Spring charged) etc.

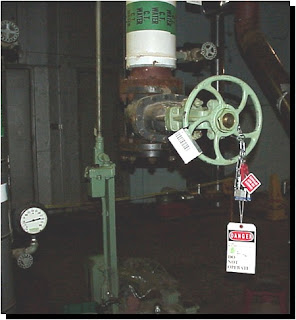

Lockout

Isolation of a source of hazardous energy, including releasing any residual hazardous energy that might be present, and securing an isolation point by locking it

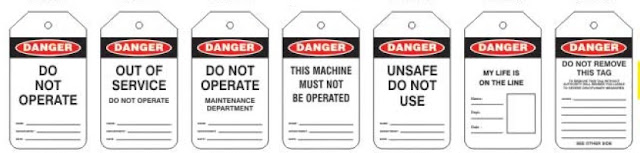

Tagging

Placing a specific

“Danger—Do Not Operate” tag on a lock or point of isolation to identify who

placed the lock and when it was placed

Tagout - Placement

of a Tag which states, “Danger—Do Not Operate” (without a lock)

Locks and Tags

Purpose of Lockout/Tagout?

When planning a Lockout, it is important to consider the nature of all hazardous energy/materials that may be present.

Lockout / Tagout is performed to prevent injury to personnel or damage to property and or environment by the unexpected release of hazardous energy or materials.

Steps to be followed for LOTO

- Identify All sources of hazardous energy prior to any LOTO.

- Remove or Control All sources of hazardous energy prior to potential exposure.

Example

- Disconnect power and discharge any capacitance

- Stop and secure rotating devices

- Lower or secure equipment to prevent movement due to gravity

- Protect equipment from external forces (e.g., wind) that may cause movement Isolate pressure sources and release pressure

- Releasing hazardous stored energy

LOTO Devices

Frequently Asked Questions (FAQ)

What is meant by lockout tagout?

Lockout tagout (LOTO) is a safety procedure used in industrial settings to ensure that dangerous machines are properly shut off and unable to start up again while maintenance or repair work is being done. The procedure involves isolating the equipment from its energy source and attaching a lock or tag to it to indicate that it should not be operated. This prevents accidental or unexpected start-up of the machine, which could cause serious injury or even death to the workers performing maintenance. LOTO is an essential safety measure that helps to protect workers in high-risk industries.

What are the 7 steps to lockout tagout?

Following are the 7 steps for lockout tagout procedure

1. Prepare for shutdown

- Identify the machine to be serviced

- Identify all energy sources that need to be isolated

2. Notify all affected employees

- Inform all personnel who may be affected by the shutdown

- Explain the reason for the shutdown and the expected duration

3. Shut down the machine

- Follow the manufacturer's guidelines for shutting down the machine

- Turn off all switches and controls

4. Isolate all energy sources

- Identify all energy sources for the machine

- Disconnect or isolate all sources of energy, including electrical, hydraulic, pneumatic, and potential energy

5. Lock out the machine

- Securely attach a lockout device to the machine's energy-isolating mechanism

- Verify that the device prevents unauthorized operation of the machine

6. Release any stored energy

- Discharge or dissipate any stored energy that may remain in the machine

- Follow the manufacturer's guidelines for releasing stored energy

7. Verify that the machine is safe to work on

- Check that all energy sources are disconnected or isolated

- Test the machine controls to ensure that they are inoperable

- Verify that the lockout device is securely attached and cannot be removed without authorization

Lockout Tagout in Different Industries

Lockout Tagout practices are applicable across various industries, including manufacturing, construction, oil and gas, mining, utilities, and healthcare. While the specific procedures may vary depending on the industry and equipment involved, the underlying principles of LOTO remain consistent—protecting workers from hazardous energy and preventing accidents.

Lockout Tagout vs. Tagout

Lockout Tagout and Tagout are terms often used interchangeably, but they have distinct meanings. Lockout refers to physically locking energy sources with a lock and key, while Tagout involves using tags to indicate that the equipment is not to be operated. While both procedures are essential, Lockout Tagout provides a higher level of protection by physically preventing accidental energization.

Conclusion

Lockout Tagout is a vital safety procedure that safeguards workers from hazardous energy sources during maintenance, repair, or cleaning activities. By implementing comprehensive Lockout Tagout programs, employers can significantly reduce workplace accidents, protect their workforce, and ensure compliance with regulatory standards. Prioritizing training, adhering to best practices, and utilizing appropriate lockout and tagout devices are essential for the successful implementation of LOTO procedures.

FAQs

Why is Lockout Tagout necessary?

Lockout Tagout is necessary to protect workers from hazardous energy sources and prevent accidents during maintenance or servicing tasks. It ensures that equipment or machinery cannot be accidentally started while workers are in potentially dangerous areas.

What are some common challenges in implementing Lockout Tagout?

Common challenges in implementing Lockout Tagout include lack of awareness, inadequate training, employee negligence, language barriers, and difficulties in coordinating multiple maintenance tasks. Proper education, training, and fostering a culture of safety can help overcome these challenges.

Are there different types of lockout devices available?

Yes, there are various lockout devices available for different types of energy sources. These devices include lockout hasps, padlocks, circuit breaker lockouts, valve lockouts, and electrical plug lockouts, among others.

Is Lockout Tagout applicable to all industries?

Yes, Lockout Tagout practices are applicable to various industries, including manufacturing, construction, oil and gas, mining, utilities, and healthcare. The specific procedures may vary depending on the industry and equipment involved.

How often should Lockout Tagout procedures be reviewed and updated?

Lockout Tagout procedures should be reviewed and updated regularly, especially when new equipment is introduced or changes are made to existing equipment. It is important to stay current with regulatory standards and industry best practices to ensure the effectiveness of the program.

What are 3 examples of lockout tagout?

Lockout/tagout is a safety procedure used to ensure that dangerous machinery and equipment are properly shut off and not started up again until maintenance or servicing work is complete. Three common examples of lockout/tagout procedures include: (1) applying a lock and tag to the power switch of a machine or equipment, (2) releasing stored energy in a machine by bleeding off pressure or disconnecting electrical power, and (3) isolating the machine or equipment from its energy source by using valves or switches to shut off power. These procedures are critical to preventing accidents and protecting workers from harm.

What are the 4 types of LOTO?

The four types of LOTO (Lockout/Tagout) include individual lockout, group lockout, tagout, and tryout. Individual lockout involves the use of a personal lock and tag by an individual worker to isolate energy sources. Group lockout involves the use of a single lock and tag by a team of workers who are working together on a machine or equipment. Tagout involves the use of a tag to indicate that a machine or equipment is not to be operated. Tryout involves the process of testing the equipment after it has been locked out to ensure that all energy sources have been effectively isolated. Proper implementation of LOTO is crucial in preventing accidents and injuries caused by unexpected energization or release of stored energy.

What is the Color Code for LOTO?

LOTO stands for "Lockout/Tagout," which is a safety procedure used to prevent the unexpected start-up or release of energy during servicing or maintenance of machines or equipment. The color code for LOTO devices such as locks and tags varies depending on the industry and country. In the United States, the Occupational Safety and Health Administration (OSHA) has established a standard color code for LOTO devices, which uses red for the lockout device and yellow for the tagout device. However, other colors may be used in different situations or industries. It is essential to follow the appropriate color code to ensure the effectiveness and safety of the LOTO procedure.

lock out tag out

ReplyDeleteFind the best respiratory protection & tool lanyard safety products at UnitedResources-Intl.Com. We offer hare online many types of safety products. Get the Confined Space Blower, cert equipment, lock out tag out safety equipment in Singapore.

http://unitedresources-intl.com/products-services/

lock out tag out

ReplyDeleteFind the best respiratory protection & tool lanyard safety equipment at UnitedResources-Intl.Com. We offer hare online many types of safety products and equipment. Get the Confined Space Blower, cert equipment, lock out tag out safety equipment in Singapore.

to get more - http://unitedresources-intl.com/products-services/

lock out tag out

ReplyDeleteFind the best respiratory protection & tool lanyard safety equipment at UnitedResources-Intl.Com. We offer hare online many types of safety products and equipment. Get the Confined Space Blower, cert equipment, lock out tag out safety equipment in Singapore.

to get more - http://unitedresources-intl.com/products-services/

lock out tag out singapore - UnitedResources is offer the best safety protective equipment in Singapore. We offer hare online many types of safety products. Get the Confined Space Blower, cert equipment, lock out tag out safety equipment in Singapore.

ReplyDeletelock out tag out singapore

ReplyDeleteFind the best respiratory protection & tool lanyard safety equipment at UnitedResources-Intl.Com. We offer hare online many types of safety products and equipment. Get the Confined Space Blower, cert equipment, lock out tag out safety equipment in Singapore.

to get more - http://unitedresources-intl.com/products-services/

cert equipment Singapore

ReplyDeleteUnited Resources - Get the best cert and respiratory protection equipment in Singapore, We offer the best cert equipment and respiratory protection equipment online at affordable prices.

to get more - https://unitedresources-intl.com/

cert equipment Singapore

ReplyDeleteUnited Resources - Get the best cert and respiratory protection equipment in Singapore, We offer the best cert equipment and respiratory protection equipment online at affordable prices.

to get more - https://unitedresources-intl.com/